Universal Packaging

The Problem

During shipping millions of packages arrive damaged at customers every year. Over 50% of customers complain that the package is delivered broken or damaged upon delivery. This means there are many packages that are being returned however sometimes the packaging is barely big enough for the product now allowing for protective material or the product is way smaller than the packaging.

The Process

Since this project was only 5 days long there was only minimal amount of time for research into current packaging methods and which ones are the best.

After doing this research I decided to base my design on suspension packaging. This type of packaging is one of the best in terms of protecting the product, however it is expensive and not flexible.

From a short ideation process looking into different methods of replicating the good features of suspension packaging I came up with the solution: UNIPACK

The Result

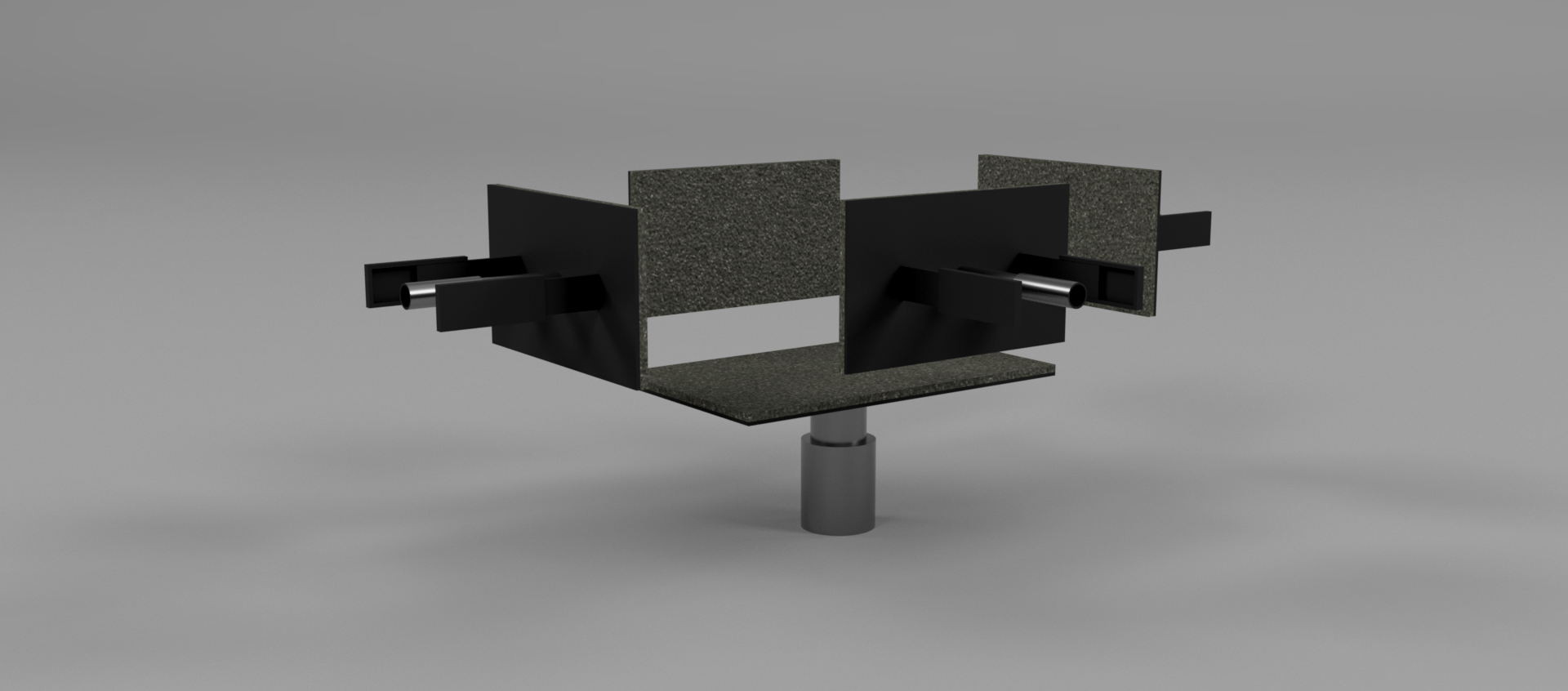

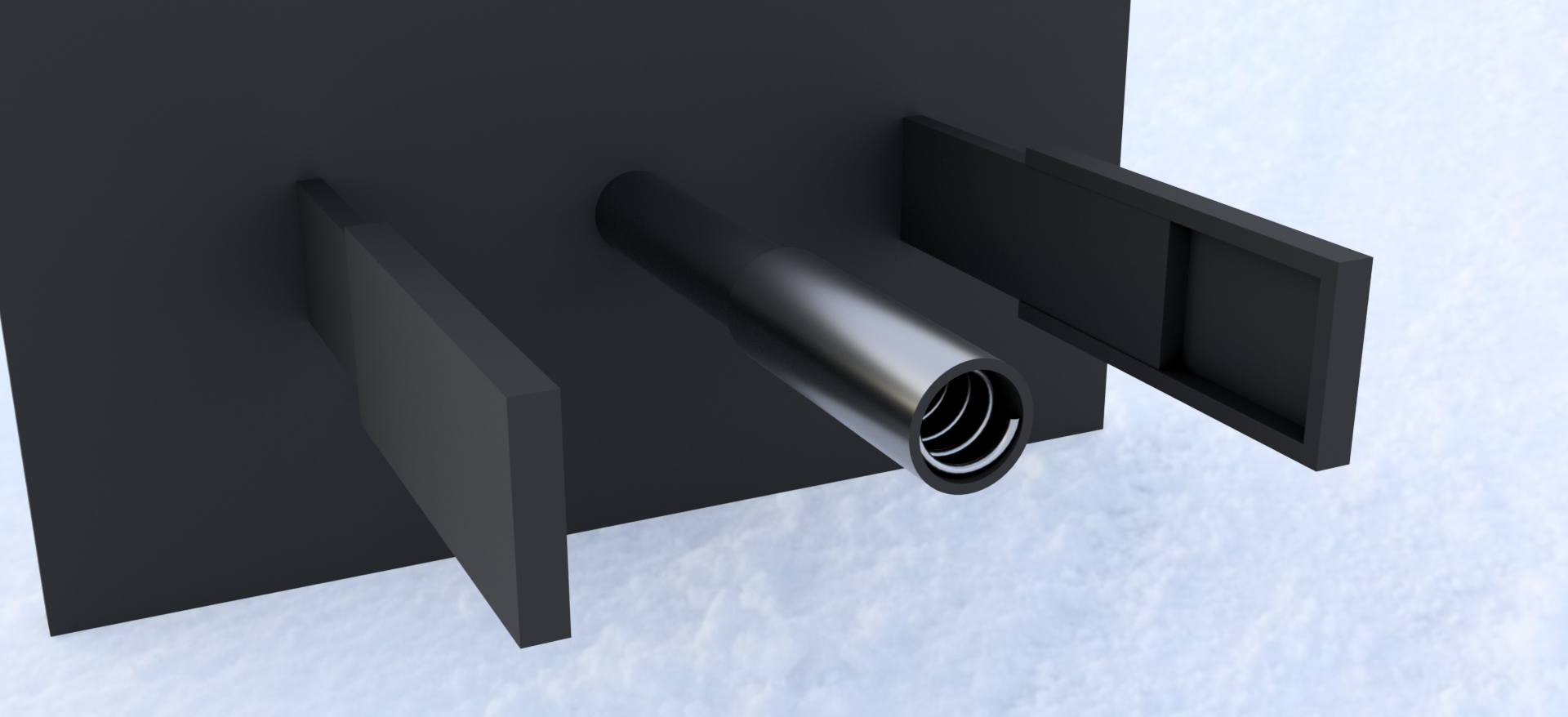

The final concept is a packaging where the product would be suspended in the middle by 5 telescopic arms that have springs inside. This would allow for a space between the packaging walls and product in case the packaging is punctured. On top of this the telescopic arms with springs would work as shock absorbers reducing the kinetic energy reaching the product itself.

These telescopic arms would also allow the required versatility of the packaging. The company using them could use the same size box for different products and have the same protection for all of them due to the ability to push these plates back and forth.

Project information

Roles: Researcher, Ideator, 3D modeller

Duration: 5 Days

Time period: Oktober/2020 - Oktober/2020

Team members: 1 member

Client: This concept was made for an assignment